OverviewIH type single-stage single-suction cantilever chemical centrifugal pump is an energy-saving and replacement product replacing F-type corrosion-resistant centrifugal pump. This product is wide

Overview

IH type single-stage single-suction cantilever chemical centrifugal pump is an energy-saving and replacement product replacing F-type corrosion-resistant centrifugal pump. This product is widely used in chemical, petroleum, metallurgy, papermaking, food, pharmaceutical, synthetic fiber and other industrial sectors. Liquids with a corrosive viscosity similar to water are conveyed. The inlet pressure of the pump shall not exceed 0.3MPa.

The temperature of the medium transported by the IH type chemical pump is generally -20°C to 105°C. If necessary, appropriate cooling measures can be used to transport liquids with higher temperatures.

Model meaning

IH50-32-160A-304

IH-international standard chemical pump

50- pump suction inlet diameter is 50mm

32 - pump outlet diameter is 32mm

160 - The nominal diameter of the impeller is 160mm

A- impeller outer diameter cutting code

304-The material of the pump contacting liquid parts is ZG0Cr18Ni9Ti

1.2 Performance range (design point); when the flow rate is 1.6-400m3/h, the head is 5-125m, and the design pressure is 1.6MPa

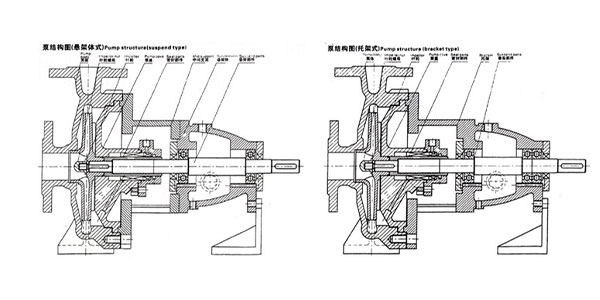

The structure description of the pump

The main parts of IH type chemical pump include pump body, impeller, impeller nut, pump cover, sealing parts, suspension parts and so on.

The structural characteristics of the pump are: the pump cover is fixed on the middle bracket through the seam, and then the pump cover is clamped in the middle through the connection between the pump body and the middle bracket port. The pump body is axial suction, radial discharge, foot support type, and can be directly fixed on the base. The suspension part is fixed on the middle support through the notch, and is supported on the base with the suspension. Overhaul can be done without dismantling the inlet and outlet connecting pipelines and pump body.

The shaft seal has various forms such as packing and mechanical seal, which can be selected according to the properties of the conveying medium and the requirements of the production process.

The pump is connected with the motor through a coupling, and the pump rotates clockwise when viewed from the drive end.

Material: According to the corrosion of the liquid, the material of the pump flow part can be selected. The main materials are SUS304, SUS316L, etc.

Pump structure diagram

IH type chemical centrifugal pump performance table

Model | Pump rated speed n=2900r/min | Pump rated speed n=1450r/min | ||||

Flow | Head (m) | Motor Power (KW) | Flow (m3/h) | Head (m) | Motor Power (KW) | |

IH25-25-125 | 3.2 | 20 | 1.1 | 1.6 | 5 | 0.55 |

IH25-25-160 | 32 | 2.2 | 8 | 0.55 | ||

IH25-25-200 | 50 | 5.5 | 12.5 | 0.75 | ||

IH25-25-250 | 80 | 7.5 | 20 | 1.5 | ||

IH40-32-125 | 6.3 | 20 | 1.5 | 3.2 | 5 | 0.55 |

IH40-32-160 | 32 | 3 | 8 | 0.55 | ||

IH40-32-200 | 50 | 5.5 | 12.5 | 1.1 | ||

IH40-32-250 | 80 | 11 | 20 | 2.2 | ||

IH50-32-125 | 12.5 | 20 | 3 | 6.3 | 5 | 0.55 |

IH50-32-160 | 32 | 4 | 8 | 0.55 | ||

IH50-32-200 | 50 | 7.5 | 12.5 | 1.5 | ||

IH50-32-250 | 80 | 15 | 20 | 2.2 | ||

IH65-50-125 | 25 | 20 | 3 | 12.5 | 5 | 0.55 |

IH65-50-160 | 32 | 5.5 | 8 | 0.75 | ||

IH65-40-200 | 50 | 11 | 12.5 | 1.5 | ||

IH65-40-250 | 80 | 18.5 | 20 | 3 | ||

IH65-40-315 | 125 | 30 | 32 | 5.5 | ||

IH80-65-125 | 50 | 20 | 5.5 | 25 | 5 | 0.75 |

IH80-65-160 | 32 | 11 | 8 | 1.5 | ||

IH80-50-200 | 50 | 15 | 12.5 | 2.2 | ||

IH80-50-250 | 80 | 30 | 20 | 4 | ||

IH80-50-315 | 125 | 45 | 32 | 7.5 | ||

IH100-80-125 | 100 | 20 | 11 | 50 | 5 | 1.5 |

IH100-80-160 | 32 | 15 | 8 | 2.2 | ||

IH100-65-200 | 50 | 22 | 12.5 | 4 | ||

IH100-65-250 | 80 | 55 | 20 | 5.5 | ||

IH100-65-315 | 125 | 75 | 32 | 11 | ||

IH125-100-200 | 200 | 50 | 45 | 100 | 12.5 | 7.5 |

IH125-100-250 | 80 | 75 | 20 | 11 | ||

IH125-100-315 | 125 | 132 | 32 | 18.5 | ||

IH125-100-400 | 50 | 30 | ||||

IH150-125-250 | 200 | 20 | 18.5 | |||

IH150-125-315 | 32 | 30 | ||||

IH150-125-400 | 50 | 45 | ||||

IH200-150-250 | 400 | 20 | 37 | |||

IH200-150-315 | 32 | 55 | ||||

IH200-150-400 | 50 | 90 | ||||