1. Brief introduction of LHY sulfur submerged pumpLHY sulfur submerged pump is suitable for transporting liquid sulfur at 130-158 degrees in various scales of sulfur acid production processes. It is a

1. Brief introduction of LHY sulfur submerged pump

LHY sulfur submerged pump is suitable for transporting liquid sulfur at 130-158 degrees in various scales of sulfur acid production processes. It is also suitable for other chemical processes that require small flow and high head. Due to the extremely high head, extremely small flow rate and extremely low specific speed of the LHY liquid sulfur pump, it is impossible to use the type of centrifugal pump to meet the performance requirements, and the performance of the vortex pump is unstable during operation, so a new technology is used to carry out Simple design, with special advantages that ordinary centrifugal pumps and vortex pumps do not have. When the flow rate of the liquid sulfur pump changes in a wide range, the head of the pump remains constant. This feature is especially suitable for chemical processes that require the pump to have self-adjusting characteristics.

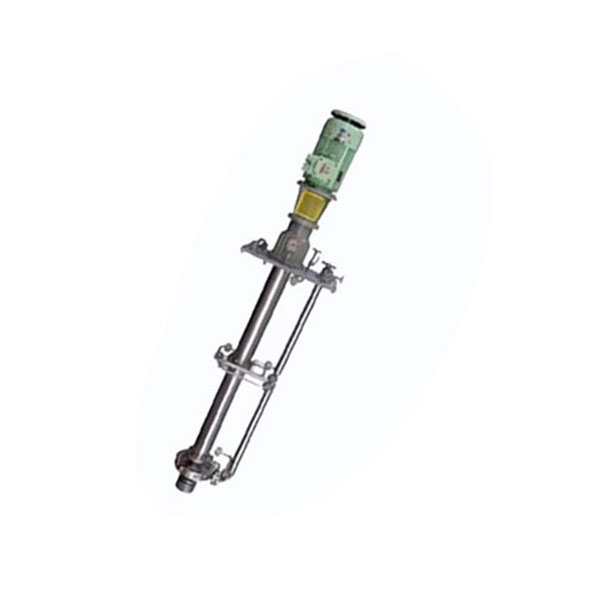

2. Structural characteristics of LHY sulfur submerged pump

This series of pumps is a vertical thermal insulation submerged pump. The outlet pipe of the pump is from the pump body, and the front pump cover is equipped with a steam or heat transfer oil insulation jacket.

This series of pumps is mainly composed of pump body, impeller, front pump cover, pump shaft, elbow, liquid outlet pipe, intermediate connecting pipe, bottom plate, bearing box, motor base and other components.

The impellers of this series of pumps are star-shaped. The structure is simple and the manufacture is convenient. The impeller has a balance hole to balance the axial force. Basically, the axial force can be considered to be completely balanced, which is of great benefit to the operation of the pump.

This series rotates counterclockwise when viewed from the motor side.

The installation dimensions of this series of pumps can be customized according to the customer's requirements.

3. Other descriptions of LHY liquid sulfur pump

Sulfur acid production is one of the important development directions of my country's sulfuric acid industry. The liquid sulfur pump with small flow rate and high lift is the key equipment for sulfur acid production. In order to meet the needs of this situation, experts from relevant design institutes and colleges With the joint efforts of our employees and our factory, we have developed the LHY series vertical liquid sulfur pump.

LHY thermal insulation liquid sulfur pump has simple structure, convenient maintenance, stable operation and stable performance.

This series of pumps is made of 1Cr18Ni9Ti material when transporting liquid sulfur. When it is used in other chemical processes, it can be made of the following materials:

304 (0Cr18Ni9) 316 (0Cr18Ni12Mo2)

1Cr18Ni12Mo2Ti 316L (00Cr18Ni12Mo2)

CW-2 (CD4MCU) J-1 (UB-6)

20Cb3 Mouel HastelloyB, C lewmet-55

When the pump transports liquid sulfur and other flammable media, it generally uses YB series explosion-proof motors, and other types of motors can also be selected according to user requirements.

Performance range:

Flow: 0.2-10m3/h

Head: 40-120m

Speed: 2900r/min

Applicable temperature range: t<=200 degrees, if special manufacturing technology is adopted, the applicable temperature can be increased to 550 degrees.

4. Performance parameters of LHY sulfur submerged pump